Alfredo Togno Foundry, since 1938.

Since 1938, Alfredo Togno Foundry has been dedicated to the transformation of raw materials, specializing in the production of aluminum alloy die-castings for third parties, with constant updates to technologies and quality standards to achieve total quality.

Thanks to the experience accumulated over the years, FTA stands out in the production of high-quality and precision die-castings for various sectors, managing design, control, processing, and finishing operations internally.

Quality is at the heart of FTA's corporate mission, certified according to UNI EN ISO 9001:2015, ISO 14001, ISO 50001 E 45001 standards. Suppliers are carefully selected, ensuring high-quality raw materials, which are tested for dimensions, integrity, and X-rays in the laboratory.

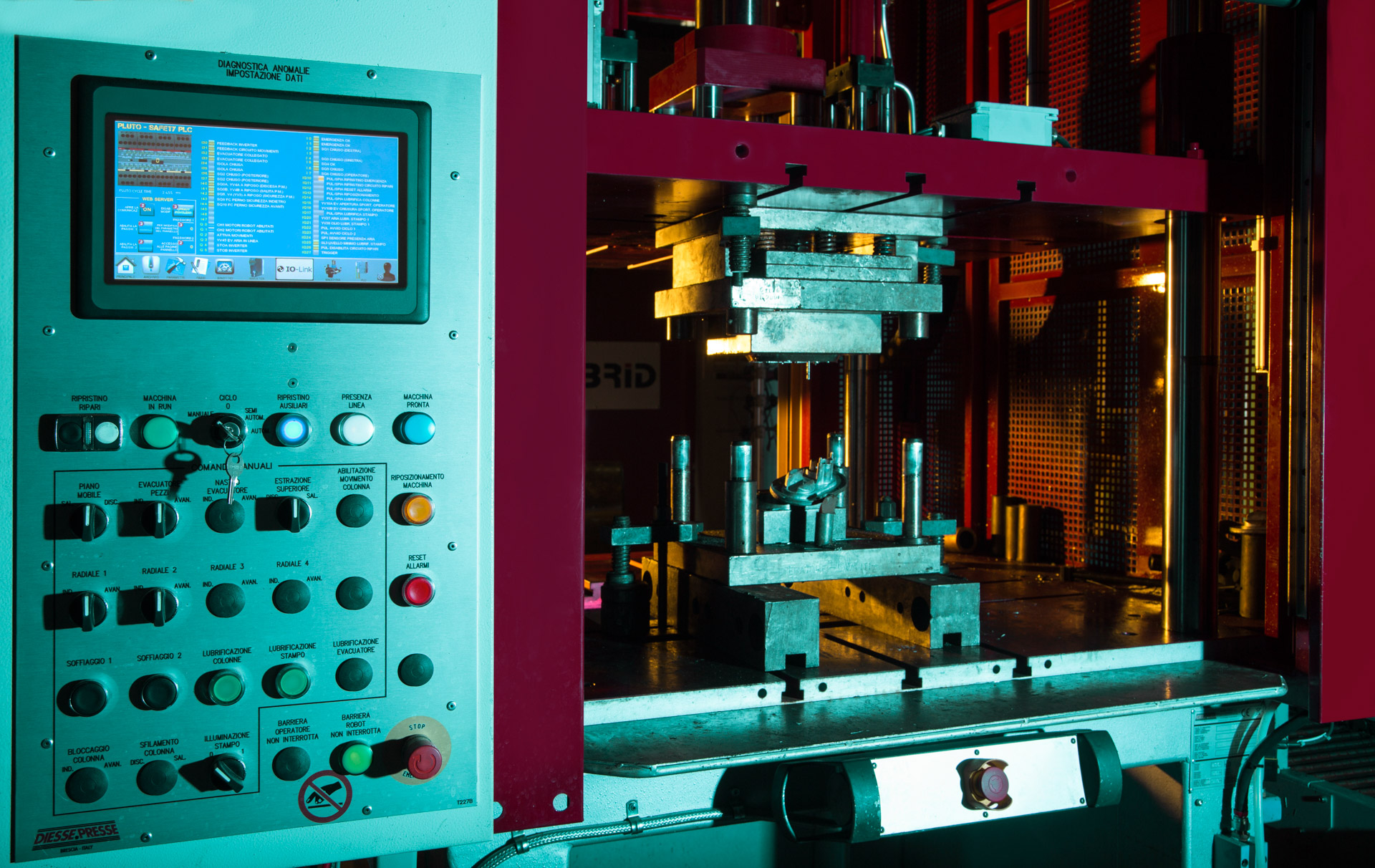

Technological Equipment

Technological Equipment

The Machinery Park

Production Capacity

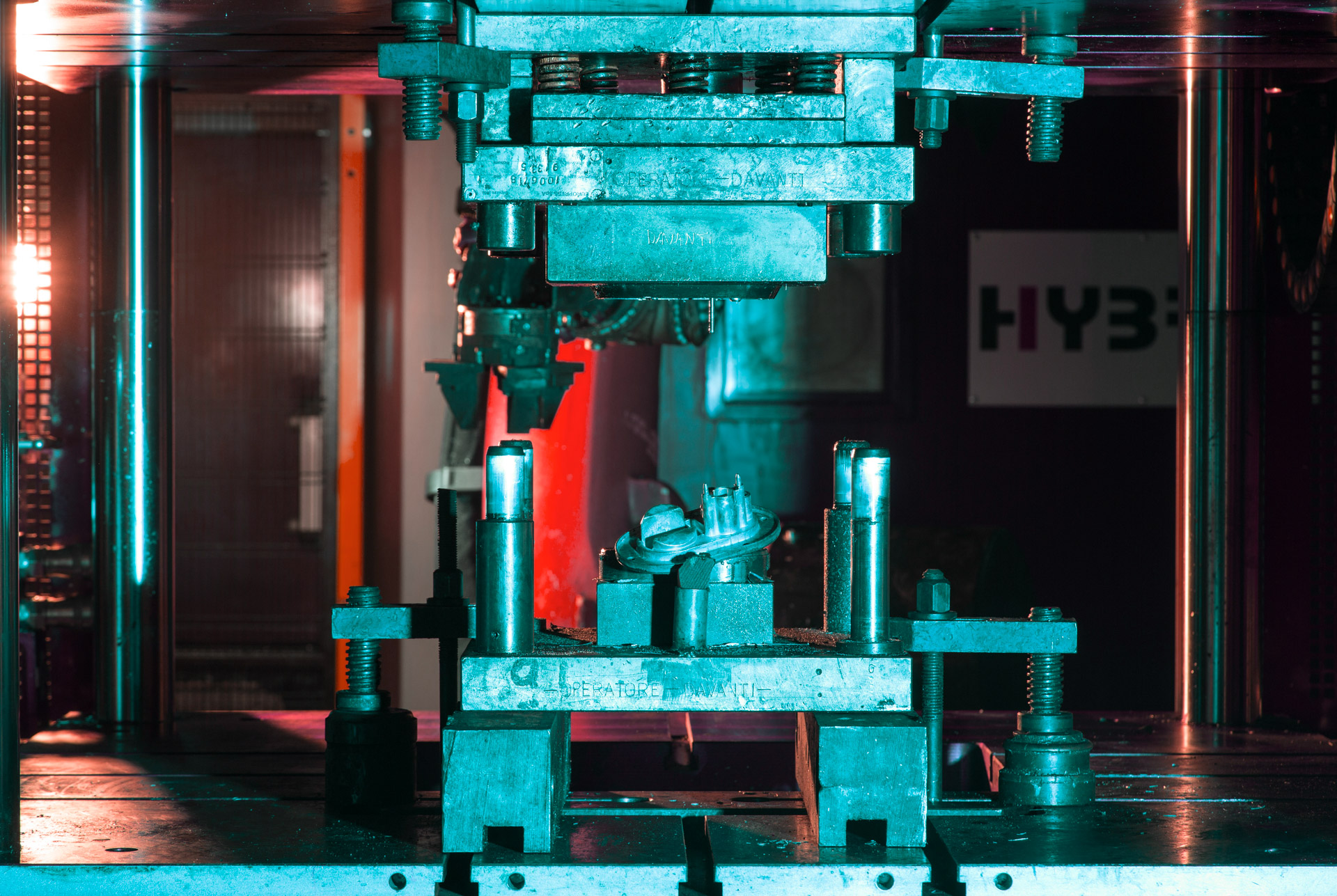

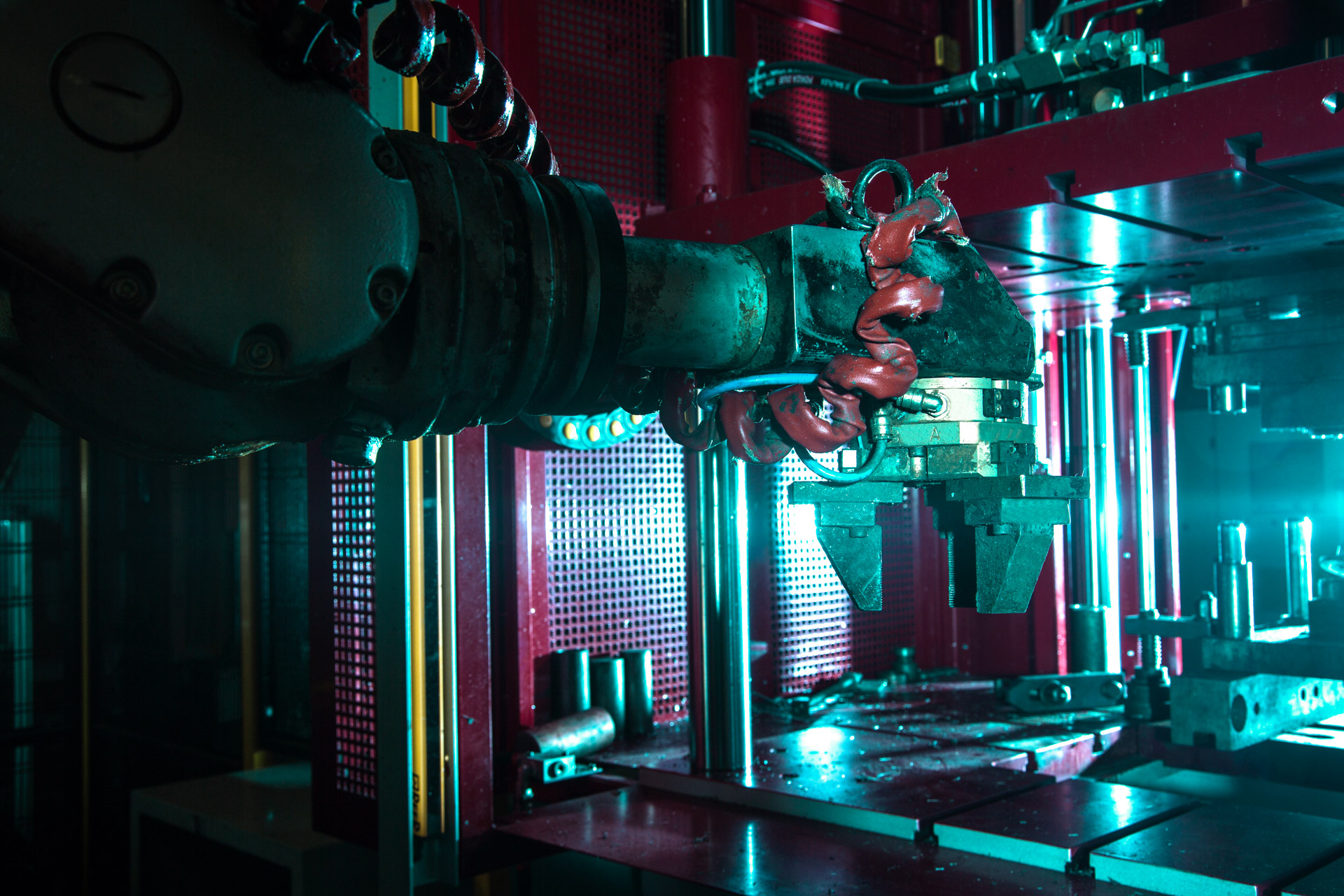

The die-casting machines at Alfredo Togno Foundry have a capacity ranging from 200 to 1000 tons of power. We work on products ranging from 5 grams to 25 kg.

Alloys Used

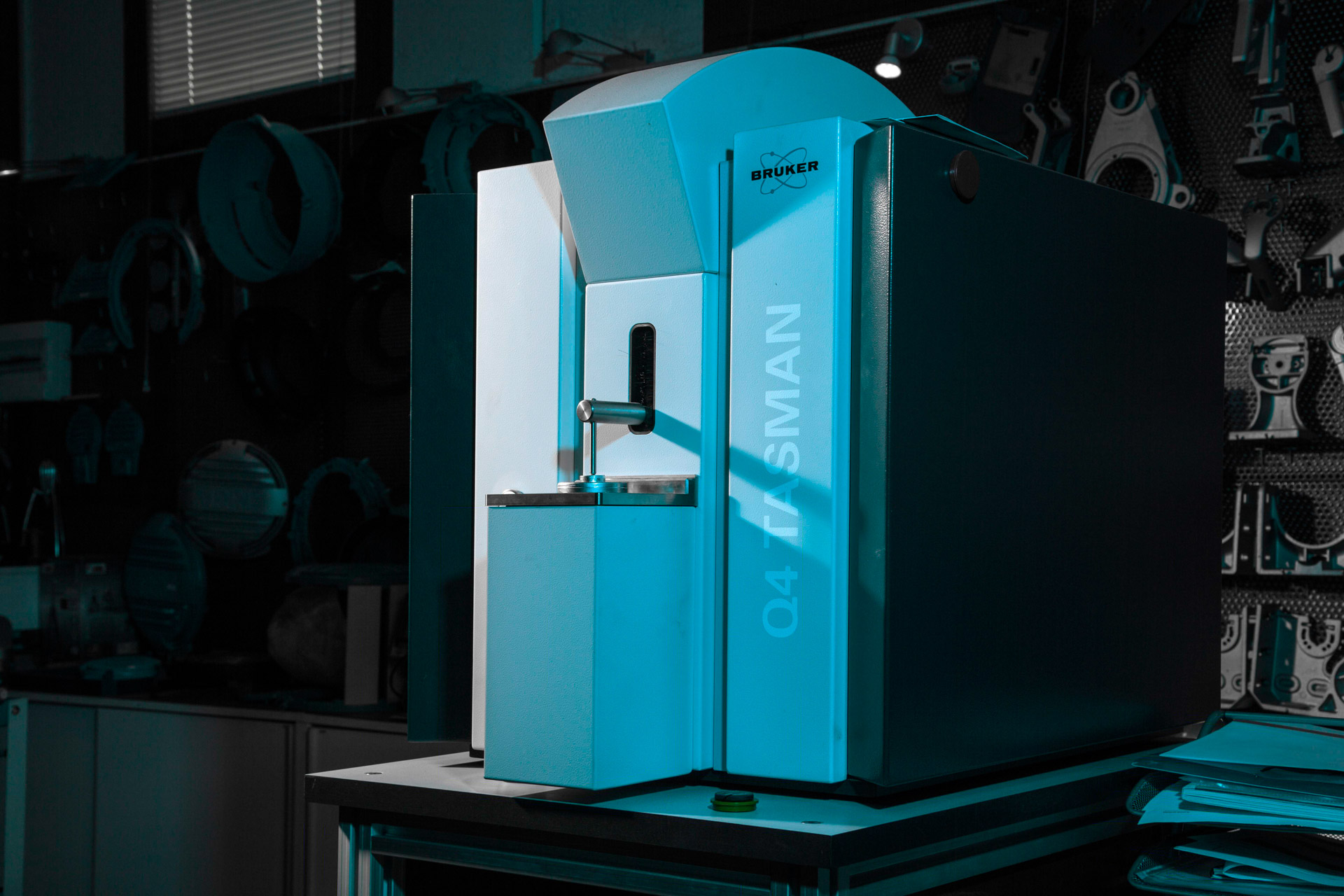

Different types of alloys are used at the foundry: ENAB46100 / ENAB46000 / ENAB47100 / ENAB43400 / ENAB44300. We have a spectrometer for the chemical analysis and composition of materials.

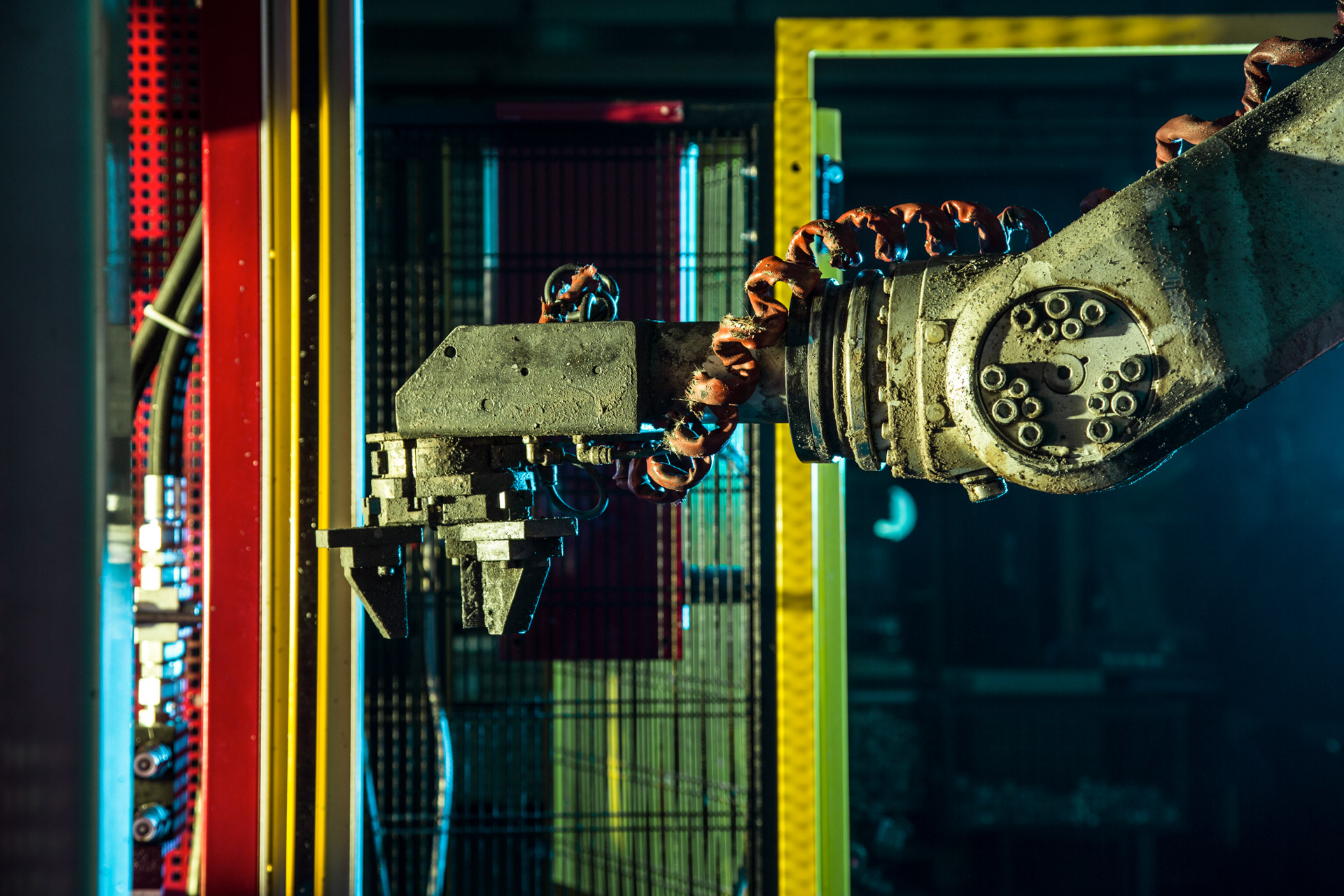

The foundry is also equipped with electric furnaces with continuous digital temperature control. To minimize defects, we constantly perform degassing and gas control in molten aluminum. Alfredo Togno Foundry also has machines for air/water leak testing and equipment suitable for finishing operations, including:

- Trimming machines

- Grinding machines for surface finishes

- Sandblasting and tumbling center

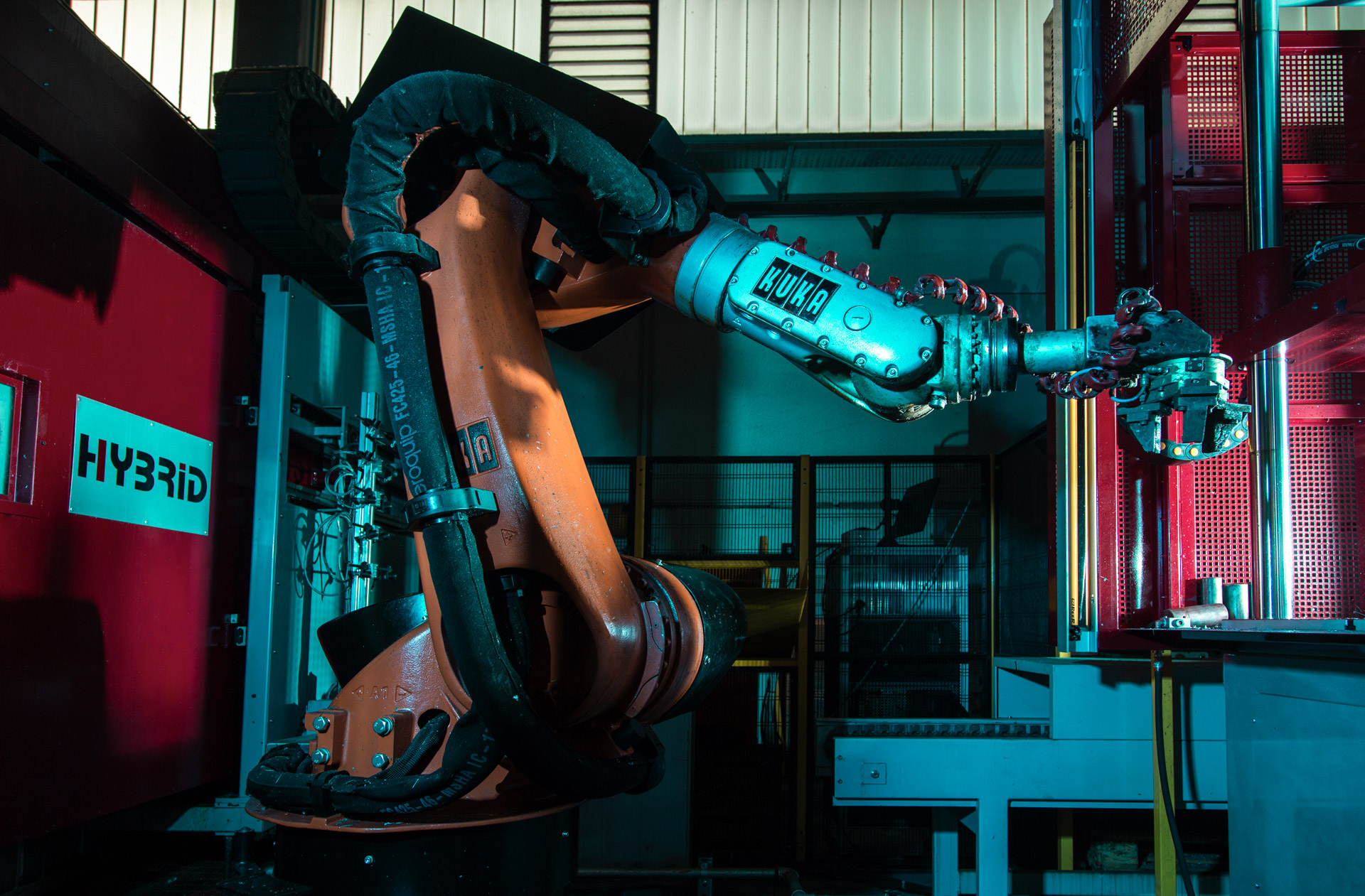

- Two-head robotic island for deburring

- CNC machining center

Logistics

Storage Service

for Fast Deliveries

We are able to offer a customer material storage service, ensuring fast deliveries and optimization of delivery batches, thus improving the overall efficiency of the logistics process.

This allows us to reduce waiting times, improve logistics efficiency, and better

meet the specific needs of each customer.

We also have:

- Automatic vertical warehouse

THE 4R PHILOSOPHY

Our supply chain,

respecting the environment.

The aluminum supply chain starts with the collection of raw materials, followed by the transformation of ingots through die-casting and processing. The finished products, used in various sectors, are subsequently collected and recycled at the end of their life cycle, creating a sustainable and environmentally friendly process.

WE ARE GREEN

We are a sustainable company

The attention to environmental issues and ecosystem protection drives the foundry to continuously invest in the technologies used, in order to minimize the pollutants generated at every stage of processing. These investments also allow us to maintain high-quality standards, evident in the finished product.