Complete Solutions,

High Standards

DIE-CASTING SURFACE TREATMENTS CONTROLS AND FINISHING MOLD MAKING USE OF EXISTING MOLDS

Thanks to accumulated experience and the use of advanced technologies, we are able to guarantee excellent products and services, meeting the highest industry standards.

Discover our services

We are proud to offer a comprehensive range of services designed to meet every need of our customers.

-

DIE-CASTINGDie-casting is a process where molten metal is injected at high pressure into a mold. Continuous technology updates and high-quality standards allow for the production of die- cast parts of the highest quality and precision. Vacuum casting options are available.

-

SURFACE TREATMENTSWe enhance the appearance and durability of our die-cast parts through advanced surface treatments. These include: heat treatments, mechanical processing, polishing, brightening, powder and liquid painting, and cataphoresis.

-

CONTROLLSAnalysis and controls are carried out throughout the production process by continuously trained personnel. Control machinery includes: 3D machines, X-rays, and leak test machines.

-

FINISHINGIn collaboration with trusted partners, the foundry offers mechanically finished products with various surface treatments according to customer needs.

-

MOLD MAKINGThe design in close synergy with the customer, the use of the latest design and 3D simulation systems, in-depth preliminary study, and prototype development allow achieving and maintaining the dimensional and quality standards of each client over time.

-

USE OF EXISTING MOLDSPossibility to use customer-owned molds, subject to careful analysis and potential adaptation to our production systems.

HIGH QUALITY

Finishing Services:

These services are managed either internally or in collaboration with trusted external companies.

Tumbling

Vibratory tumbling is carried out using 6 circular bowl vibrators. Loading and

unloading of die-cast parts is done manually or automatically, depending on the delicacy of the parts.

Trimming

Trimming operations are performed by 6 trimming presses with tonnage ranging from 20 to 40 tons. Trimming dies are made by qualified and specialized external companies.

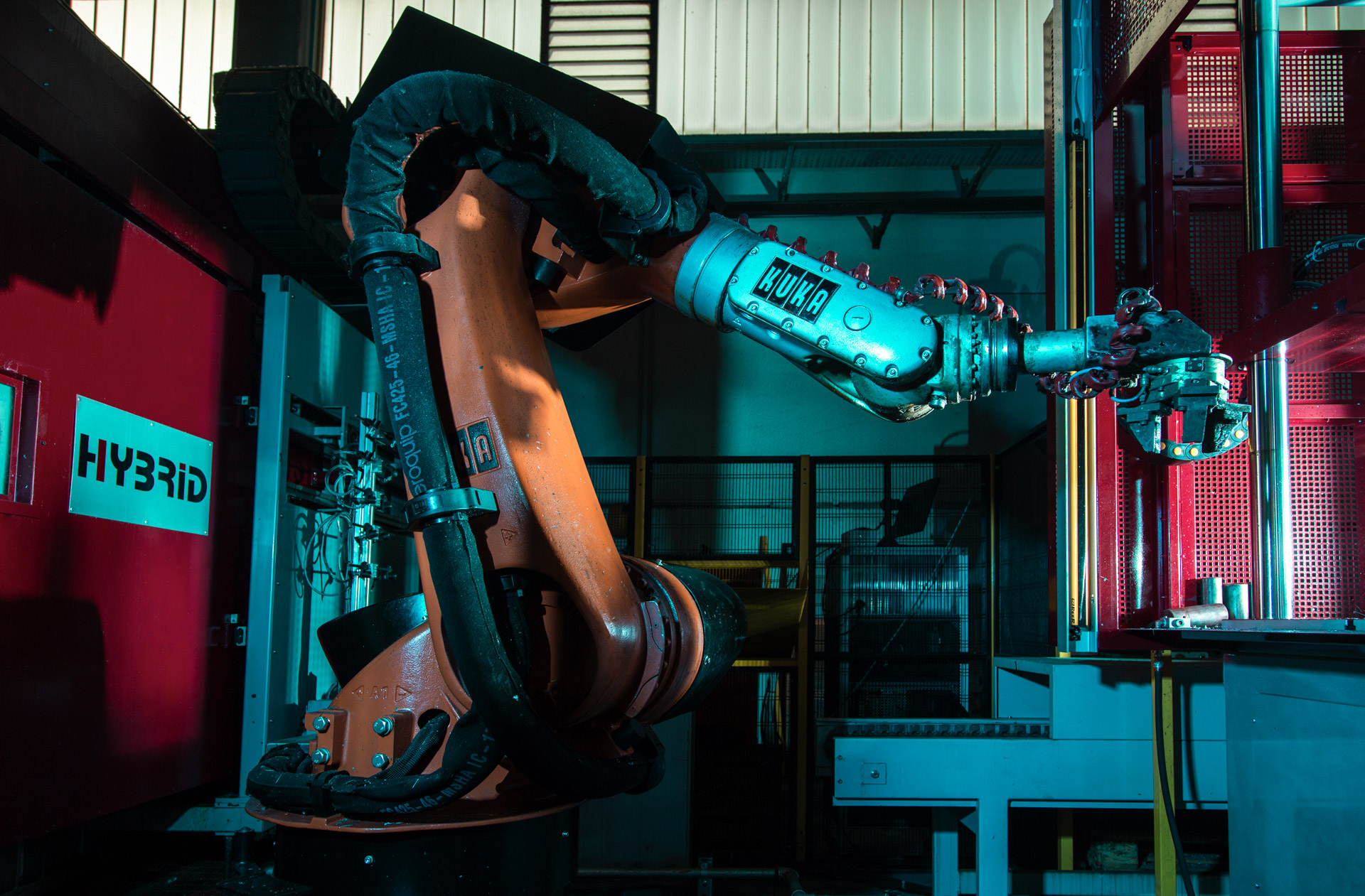

Deburring

Deburring, grinding, polishing (hand/balls), and satin finishing operations are carried

out manually on a belt or using modern robots.

Sandblasting

Rotary, belt, or cluster sandblasting. The surface of the product, once sandblasted,

becomes porous, enhancing any subsequent painting.

Painting

The ability to choose from a wide range of colors and powders allows us to meet

the diverse needs of individual customers.