Alfredo Togno Foundry.

Sustainable Quality,

Innovation, and Design.

SCROLL TO LEARN MORE

TOGNO FOUNDRY

Committed to quality. Since 1938, we have been continuously investing in machinery.

Attenti alla qualitá. Dal 1938 investiamo costantemente in macchinari.

Founded in 1938, Alfredo Togno Foundry is an extremely versatile foundry that utilizes some of the most important raw material transformation technologies.

Business Areas

Business Areas

1. Medical

Our foundry manufactures precision components for the medical sector, ensuring high- quality standards and compliance with international regulations for medical equipment and devices.

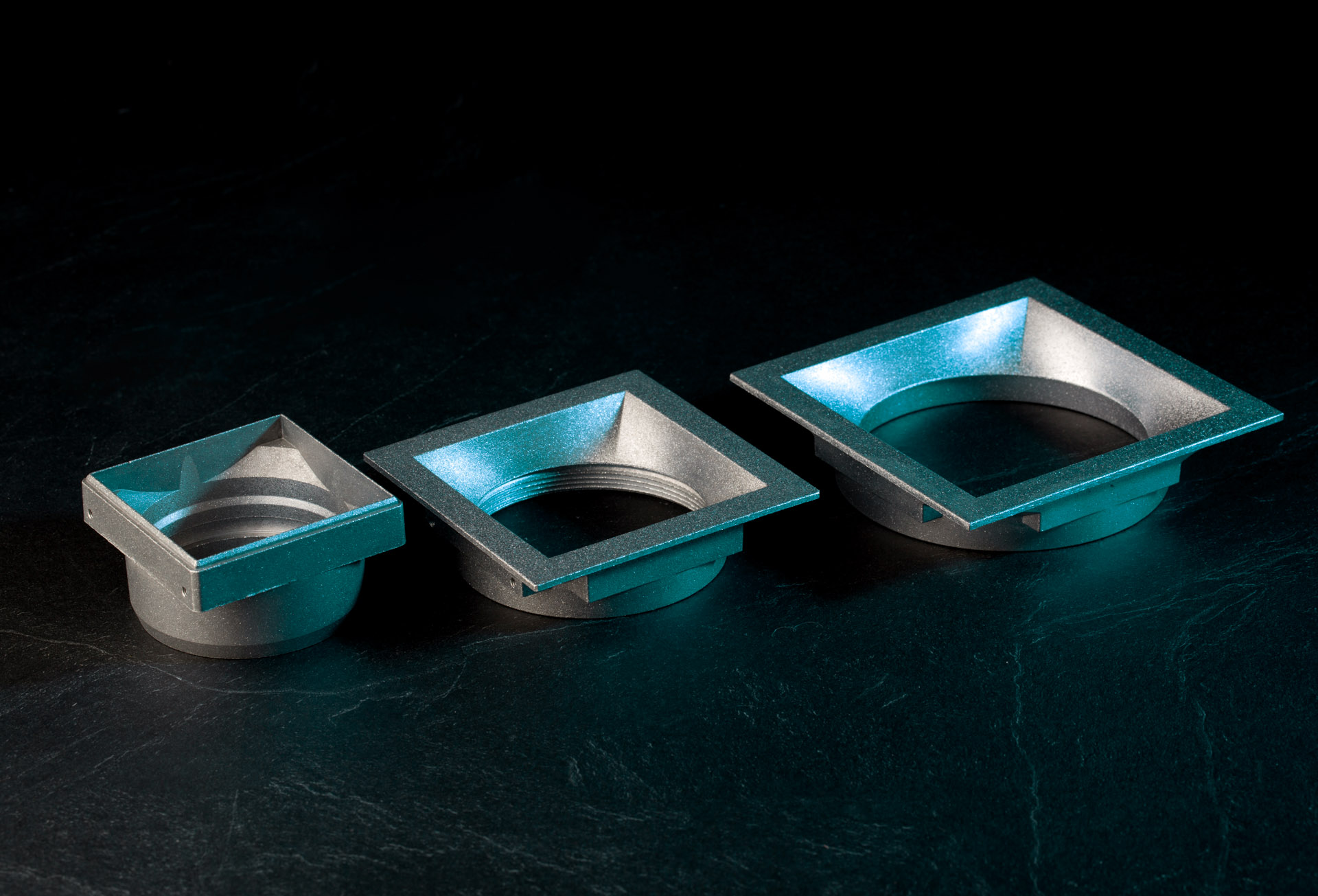

2. Lighting

Specialized in creating components for lighting systems, we offer innovative and high- quality solutions for architectural and decorative projects.

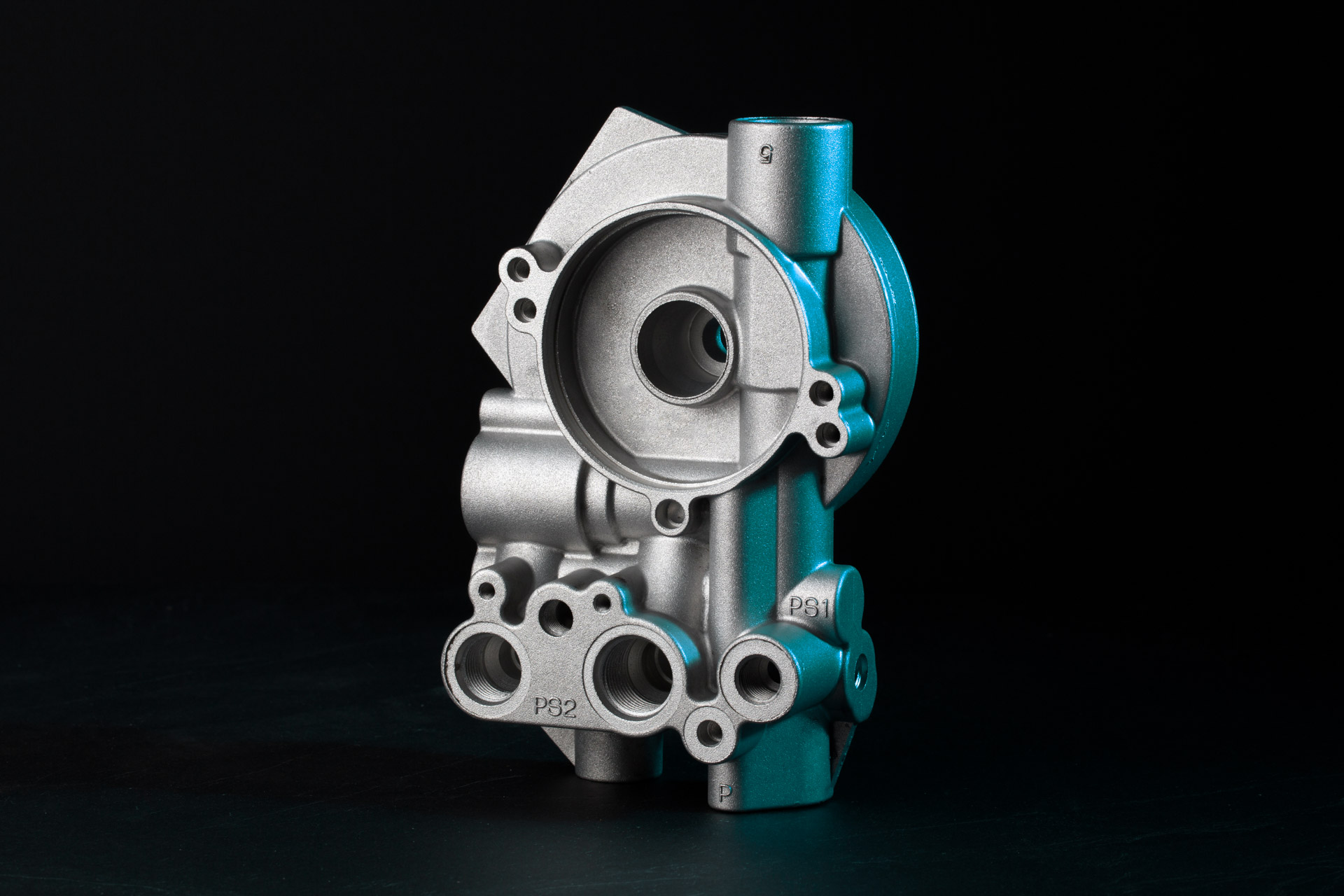

3. Automotive

We produce metal parts for the automotive sector, ensuring reliability and durability through advanced casting techniques for engines, transmissions, and bodywork.

4. Furniture

We manufacture metal elements for the furniture sector, offering refined designs and customized solutions for furniture and home accessories.

Capable of Handling Every Stage of the Production Process .

FROM CO-DESIGN TO PRODUCTION AND FINISHING. THANKS TO OUR EXPERIENCE, WE CAN PROVIDE A CERTIFIED QUALITY CONTROL SERVICE.

Design

We provide quick and cost-effective prototypes using silicone molds and 3D printing, ensuring the quality of the final product. In-house mold maintenance in Gravellona Toce ensures timely interventions thanks to close collaboration with our designers.

Co-Design

We adopt a co-design policy in close collaboration with customers, using the latest 3D CAD design systems. This approach allows for comprehensive project planning, ensuring the achievement and maintenance of the agreed dimensional and quality standards.

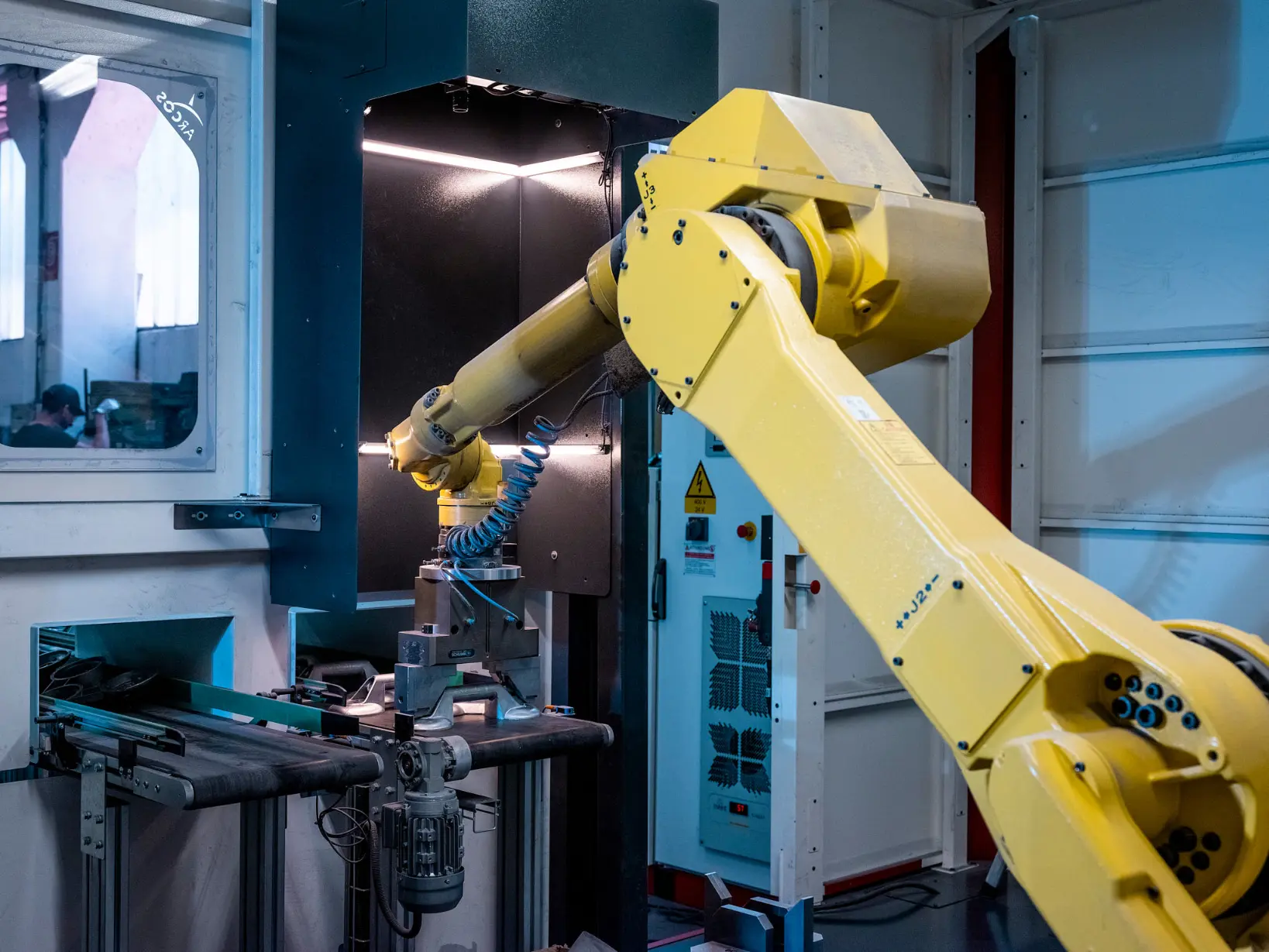

Production

We have 8 automated cold chamber die-casting machines, with a power range from 200 to 1000 tons, managed by qualified personnel.

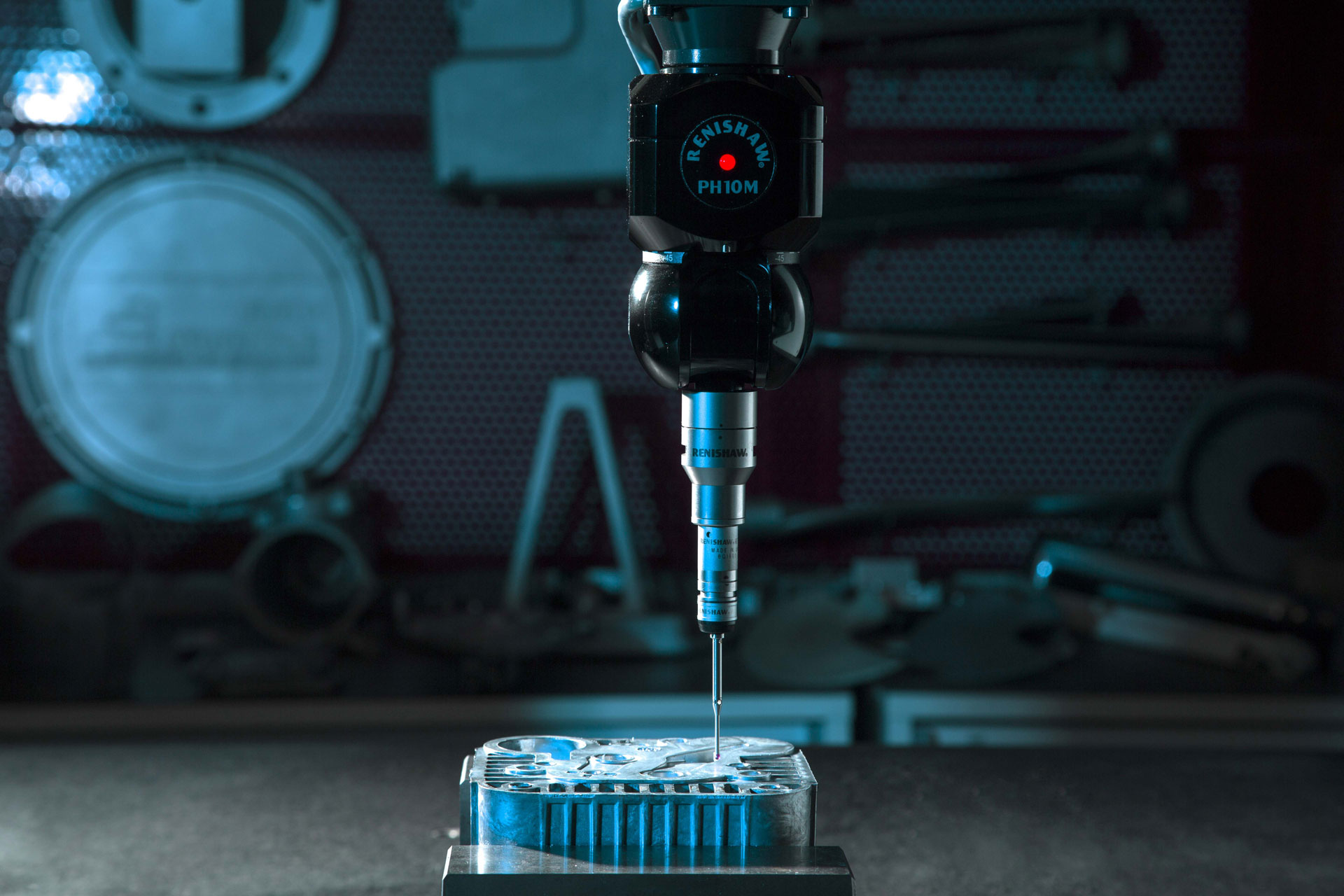

Quality Control

Quality is the main component of FTA's corporate mission. For this reason, the company obtained the international UNI EN ISO 9001:2000 certification in February 2003.

Finishing

FTA offers a complete service to the customer thanks to a range of machines for finishing die-cast parts. The main finishing operations are carried out directly within the plant.OUR SERVICES

In the Spotlight

Thanks to the accumulated experience and the use of advanced technologies, we are able to guarantee excellent products and services, meeting the highest industry standards. Discover all services

-

Surface TreatmentsWe improve the appearance and durability of our die-cast parts through advanced surface treatments. These include: heat treatments, mechanical processing, polishing, brightening, powder and liquid painting, and cataphoresis.

-

Die-CastingDie-casting is a process where molten metal is injected at high pressure into a mold. Continuous technology updates and high-quality standards allow for the production of die- cast parts of the highest quality and precision. Vacuum casting options are available.

-

Mold MakingThe design in close synergy with the customer, the use of the latest design and 3D simulation systems, in-depth preliminary study, and prototype development allow achieving and maintaining the dimensional and quality standards of each client over time.

-

Use of Existing MoldsPossibility to use customer-owned molds, subject to careful analysis and potential adaptation to our production systems.

-

Controls and FinishingAnalysis and controls are carried out throughout the production process by continuously trained personnel. Among the machines used for control are: 3D machines, X-rays, and leak test machines.

Production Capacity

Learn everything about the technological equipment within Togno Foundry.Learn more